Tesla's Aluminum Welding Certification is a groundbreaking initiative ensuring the structural integrity and safety of electric vehicles (EVs) by implementing superior welding standards for aluminum car bodies. This certification, relevant to collision repair and auto body restoration, guarantees that every weld meets precise quality control, fostering robust connections and enhancing passenger safety. Skilled technicians perform these welds, identifying and rectifying potential defects through rigorous testing, ensuring even seemingly minor repairs like dent removal are handled structurally soundly. Ultimately, this process streamlines collision repair, reduces costs, and preserves the aesthetic appeal of Tesla automobiles.

Tesla’s aluminum welding certification sets a new standard for structural integrity in the automotive industry. This innovative program ensures that every welded component meets rigorous quality control measures, critical for electric vehicle (EV) performance and safety. By certifying specialized welding techniques, Tesla guarantees the strength and durability of its aluminum structures, enhancing overall vehicle reliability and contributing to lighter, more efficient EV designs.

- The Significance of Tesla's Aluminum Welding Certification

- How the Certification Ensures Structural Integrity

- Benefits and Applications in the Automotive Industry

The Significance of Tesla's Aluminum Welding Certification

Tesla’s Aluminum Welding Certification is a significant step forward in ensuring structural integrity in their vehicles. With aluminum becoming a prominent material in modern car manufacturing, especially in electric vehicle (EV) production, proper welding techniques are crucial. This certification guarantees that Tesla’s vehicles meet the highest standards for aluminum welds, ensuring both strength and durability.

This initiative is particularly relevant in the context of automotive collision repair and auto body restoration. The certification assures consumers and repair shops that Tesla vehicles can be safely repaired and restored with precision, preserving their structural integrity. Even when dealing with seemingly minor issues like car dent repair, this certification provides peace of mind, knowing that every weld is up to par, contributing to the overall safety and reliability of Tesla’s electric vehicles.

How the Certification Ensures Structural Integrity

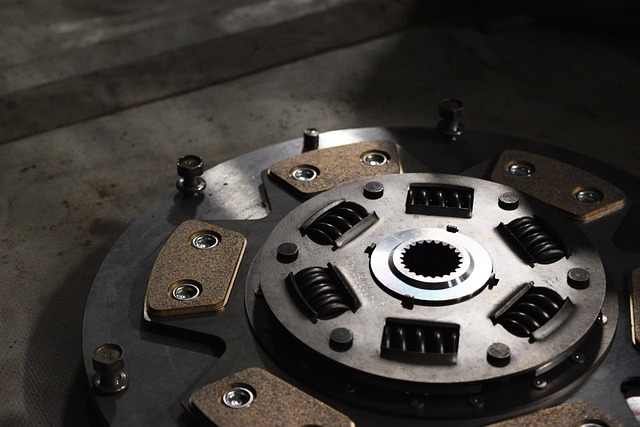

The Tesla Aluminum Welding Certification is a crucial standard that guarantees the structural integrity of Tesla vehicles. This certification ensures that every weld on an aluminum car body meets stringent quality control measures, ensuring robust connections between components. Skilled technicians, equipped with specialized knowledge and tools, perform these welds, adhering to precise specifications. By doing so, they create seamless joints that withstand the rigors of daily driving, enhancing the overall safety and reliability of the vehicle.

Moreover, this certification process involves rigorous testing and inspection to identify any potential weaknesses or defects. This meticulous approach not only repairs but also prevents issues like car scratch repair or more severe collision damage in a collision center. The end result is a sturdy structure that ensures passenger safety, improves vehicle longevity, and maintains the aesthetic appeal of Tesla automobiles.

Benefits and Applications in the Automotive Industry

The Tesla Aluminum Welding Certification is a game-changer for the automotive industry, revolutionizing vehicle repair and auto body work processes. This specialized skill set ensures that repairs, especially in the realm of auto collision repair, maintain unparalleled structural integrity. With aluminum becoming a prevalent material in modern car manufacturing, the certification highlights the importance of proficient welding techniques to meet contemporary standards.

The benefits are clear; certified welders can deliver precise, robust, and durable connections, enhancing safety and vehicle performance. This is particularly advantageous for complex auto body work, where structural soundness is paramount. Moreover, it streamlines the repair process, reducing time and costs associated with traditional methods, making it a valuable asset for any automotive workshop or collision center.

Tesla’s aluminum welding certification sets a new standard for structural integrity in the automotive industry. By ensuring precise and robust welds, this certification enhances vehicle performance, lightens weight, and contributes to more efficient manufacturing processes. With its superior strength-to-weight ratio, aluminum offers significant advantages over traditional materials, making Tesla’s commitment to excellence through this certification a game-changer for the future of sustainable and high-performance vehicles.